The Fixture Rabbithole

After completing my center steer hub, I had the urge to build a dedicated cargo bike frame fixture. The large form factor of cargo frames is generally incompatible with common welding fixtures, so I was inspired to create a modular system that made framebuilding a breeze.

I ultimately chose a 60x60mm extrusion for the main fixture rail which provides mounting for various sliders and other fixture pieces. Early in the design, I knew I wanted a rotisserie-style fixture to improve joint access during welding. I welded two stands out of some scrap table cutoffs and machined a bearing housing with Acetal bushings for smooth operation. The fully loaded fixture can easily rotate past 90 degrees in either direction from vertical and locks into place using adjustable handles.

All fixture components interface with the main extrusion via sliders. Each slider rides on ball bearings within the extrusion T-slot and is tensioned by eccentric hex nuts I machined out of steel. I also added hardened rails with locating cylinders to hold frame tubes during the tacking process.

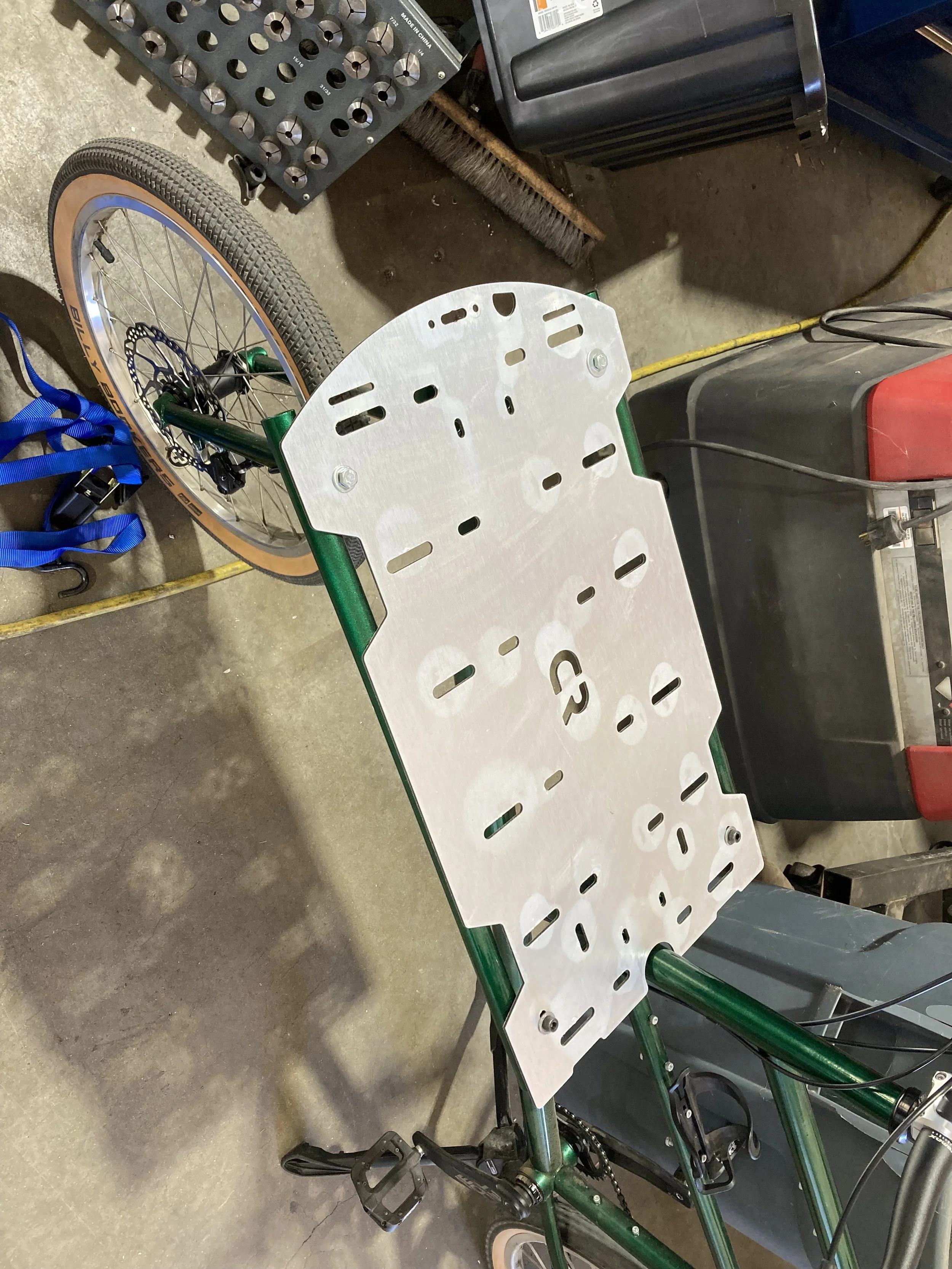

The best way to test the frame jig was to build a new bike frame! I wanted a snappy, lightweight bike that solved the handling gripes I had with my previous “truck-like” cargo bike. I based the frame design around the Omnium cargo bike with some personal touches scattered throughout, including a ACM cargo bed, dropped seatstays, middle mounting tube, and a modular steering system. Currently, the bike uses a 1:1 balljoint system, but can easily be swapped to chain, cable, or other methods of steering mechanisms.