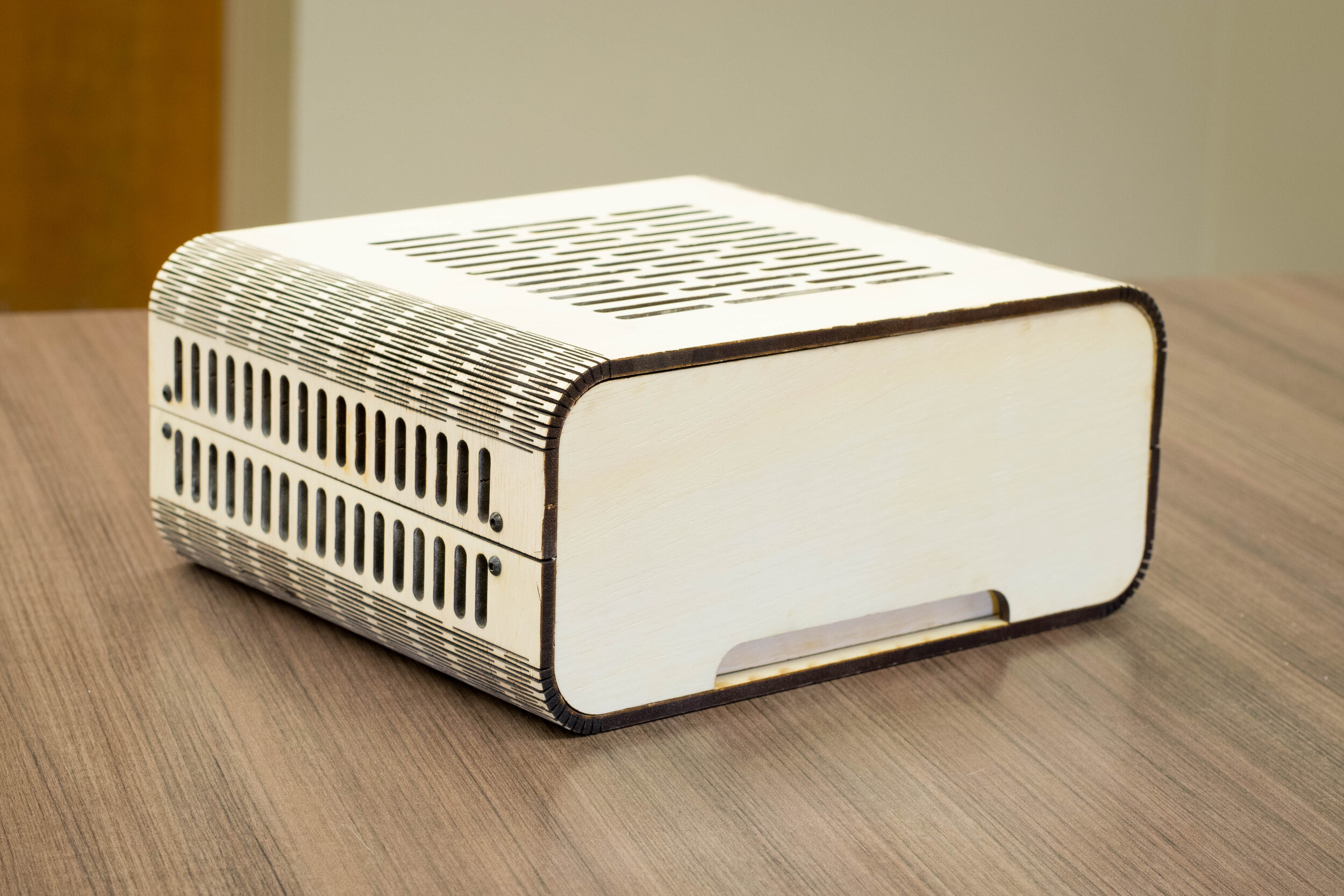

WOODSTOCK

I created several computer cases that utilize a “living hinge” design achieved through laser cutting. These cases are made out of readily available, low-cost plywood and feature smooth large-radius bends usually achieved through expensive sheetmetal press dies.

Due to a shortage of online information, I refined the living hinge pattern relief and laser cutter settings over many prototypes. I eventually found a mathematical relation that produces consistent living hinge patterns capable of tight radius bends. I designed all cases using the sheetmetal tools in Fusion 360 and generated flat patterns of all panels before adding the cut patterns.

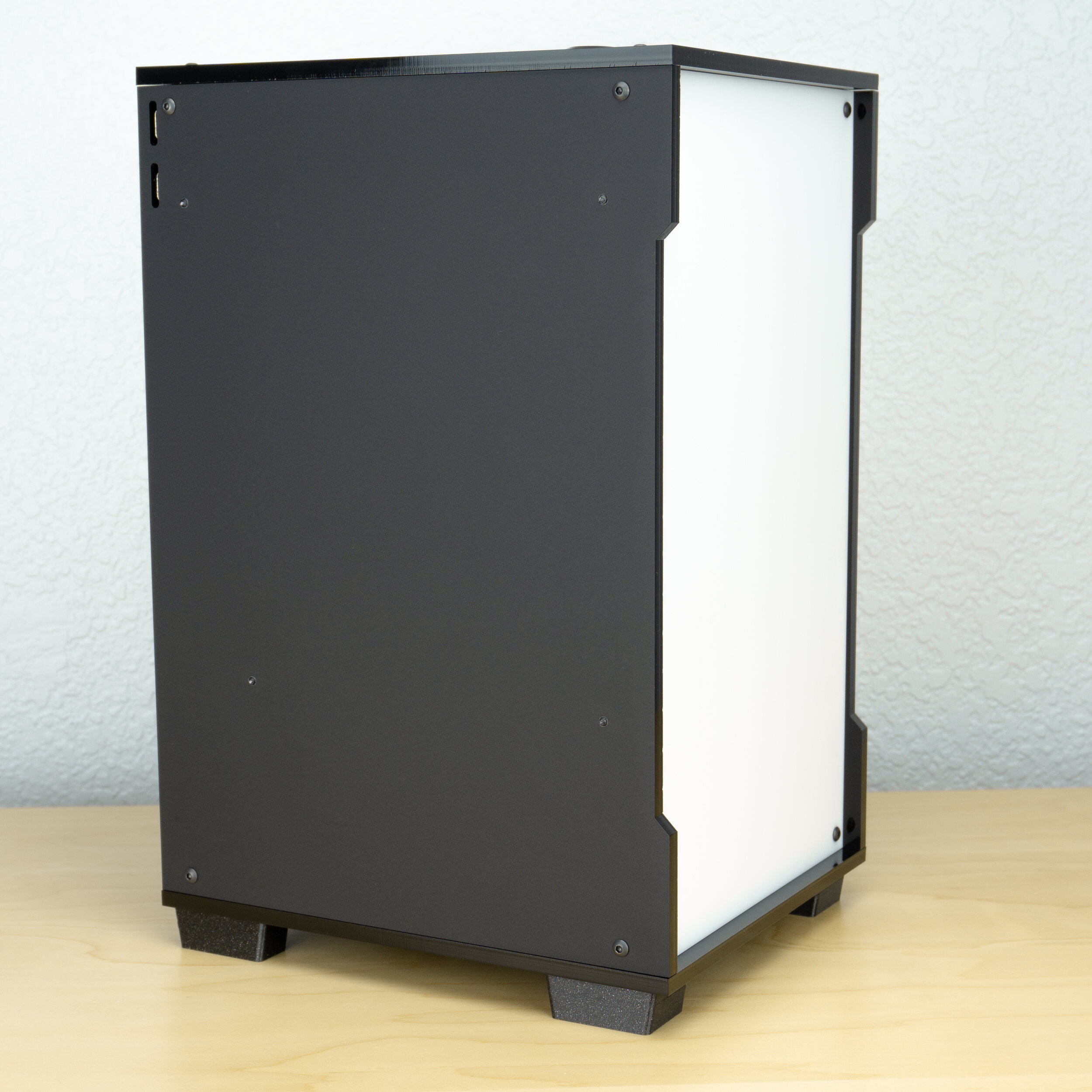

SC-09

SC-09 is an open-source computer case designed to best combine price, space-efficiency, and functionality. The fundamental design takes cues from many previous projects - namely, the use of acrylic sheets for structure, flexible component mounting points, and a modular flat-packed design. All 3 were essential in reaching a low target cost as it enabled a reduction in total part count, shipping costs, and production time.

Audience

While a somewhat niche audience, the small form factor (or SFF) community expressed considerable interest in the project’s first prototypes/concepts. I used the subreddit /r/sffpc, one of the largest communal forums for the hobby, to seek feedback and constructive criticism from the community and applied it to the final product. I was also able to leverage the first few buyers as volunteer product testers, who gave specific feedback about the build process and offered improvements.

Final Implementation

I wanted to create the most complete, seamless experience possible for the end user. The digital instructions were modeled after the design ethos of Lego/IKEA manuals, and the case is shipped flat packed with each individual panel protected. The design pays careful attention to space efficiency in production+transport, and fits tightly on a standard 16x24” sheet of cast acrylic (to be laser cut) and into a USPS Priority medium box. The layout of parts, both laser cut and 3D-printed, is meant to reduce heat warpage and increase strength where possible while remaining easy to machine on any consumer machine.

Notable Features

Compact 9L External Volume with ITX GPU and small tower CPU cooler compatibility

Modular drive mounting slots, up to 9x drives in parallel

Twin 80mm Exhaust fans, 1x 120/140mm intake

Fast and straight-forward assembly process (panels/hardware pre-threaded and threaded inserts installed)