Measuring the Frame Geometry

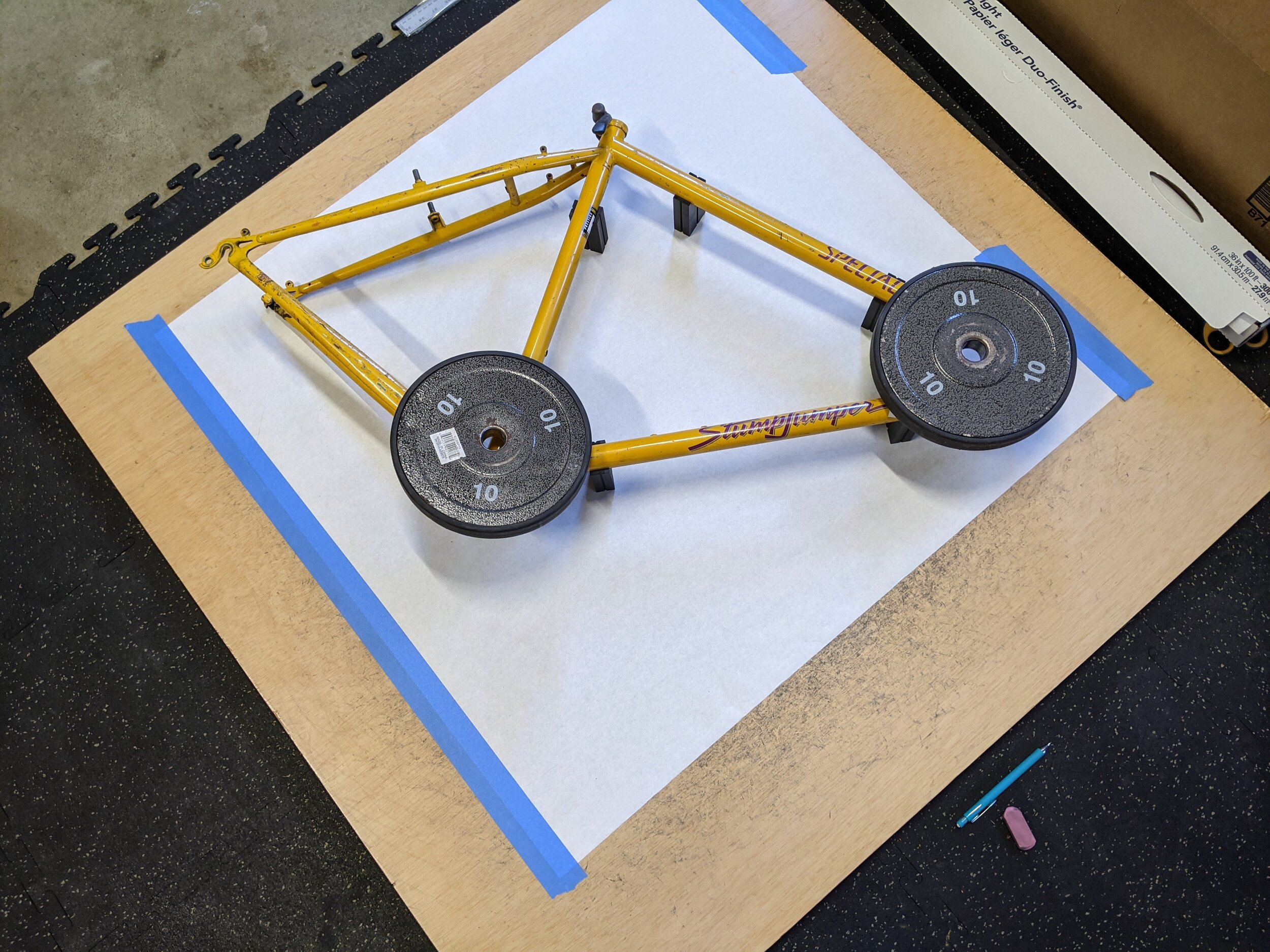

In order to save time and significantly simplify my frame jig, I chose to use an old Specialized Stumpjumper frame for the rear of the cargo bike. The Stumpjumper frame is made out of straight-gauge chromoly, which will hopefully be straightforward to weld (I really only need to weld at the top tube and bottom bracket shell).

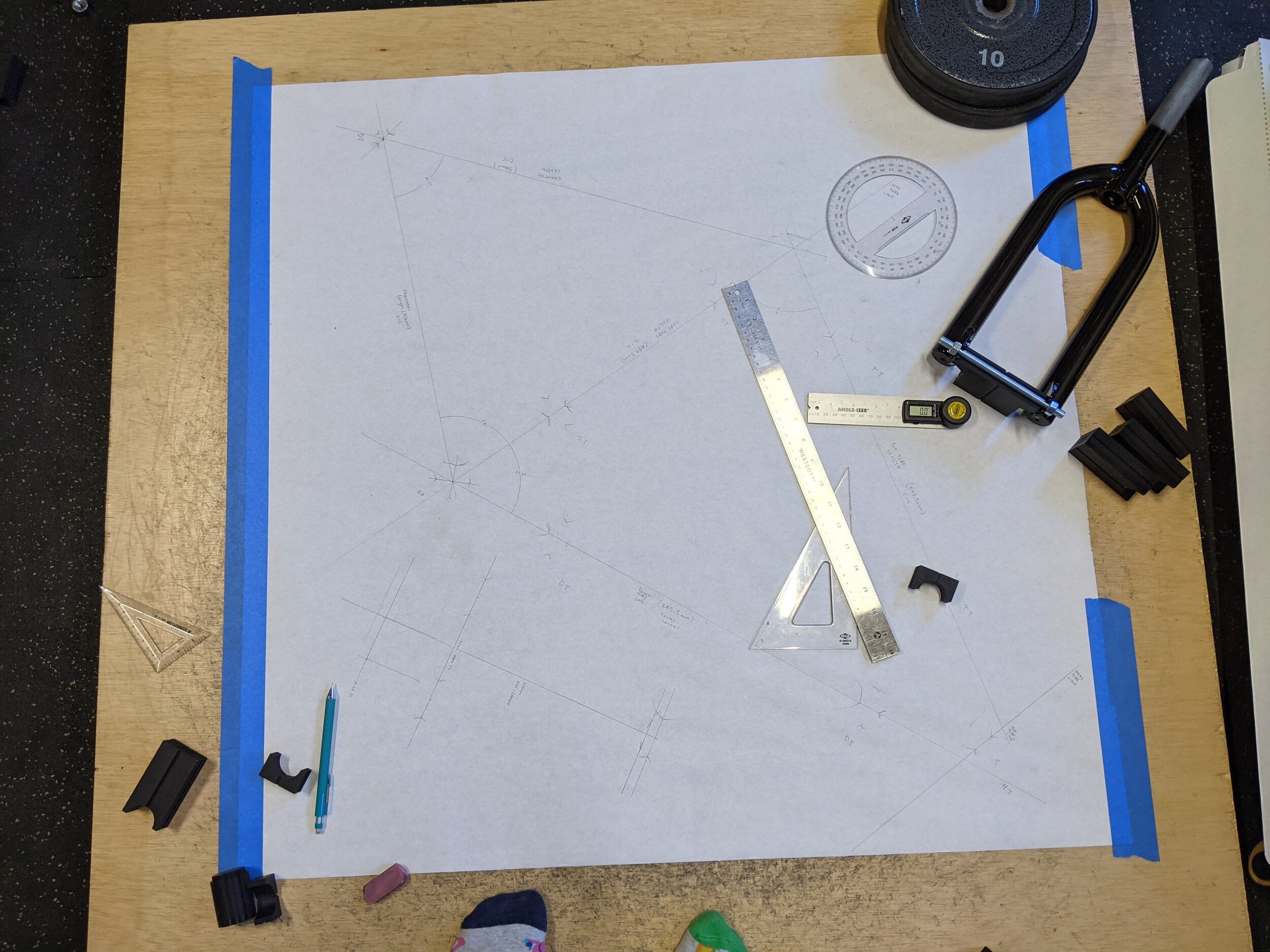

I couldn’t find any frame geometry numbers in a web-archived catalog; thus, I needed to find a way to physically measure the frame. To achieve this, I designed and 3D-printed standoffs that allowed me to orthographically project the frame onto a piece of paper (which I could subsequently measure).

The standoffs attach to either a frame tube or another important frame component like the bottom bracket or rear dropout. Each standoff has small indentations at the width and length midpoint; these indentations allow me to accurately mark the centerline of each frame tube.

After recording the necessary measurements, making an dimensionally accurate CAD model of the frame was straightforward. I plan to start cutting tubes and assemble the frame jig very soon.